Fibre optic network connection can’t be achieved without optical transceiver and patch cable. Optical transceiver varies from transmission media, interface, transmission distance, data rate, and brand, for example, SFP for 1000Mbps, SFP+ for 10G, QSFP+ for 40G, CFP and QSFP28 for 100G. It’s not difficult to identify these optical transceivers. But when you connect the optical transceiver to the patch cable, many details need to be noticed. This article will give you advice on how to choose the suitable patch cable for your optical transceiver.

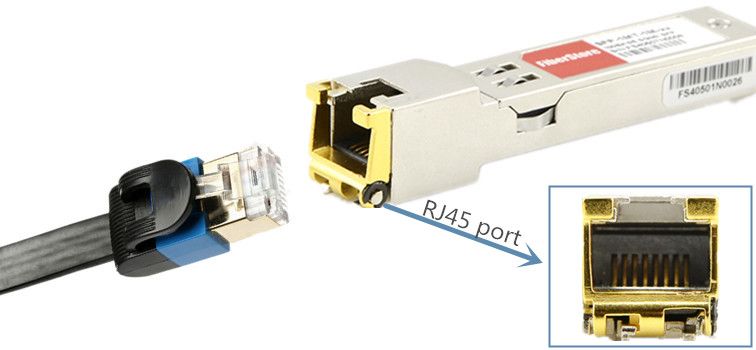

According to transmission media of fibre optic and copper, transceivers can be divided into two kinds, copper based transceivers and fibre optic based transceivers. MSA has defined several copper based transceiver like: 100BASE-T, 1000BASE-T and 10GBASE-T. Copper transceivers are available in GBIC, SFP and SFP+ form factors, which usually has an RJ45 interface. So Cat5/6/7 cables are typically used to connect with the transceivers. Maybe Cat8 will be researched and developed to support higher data rate up to 40G sooner or later.

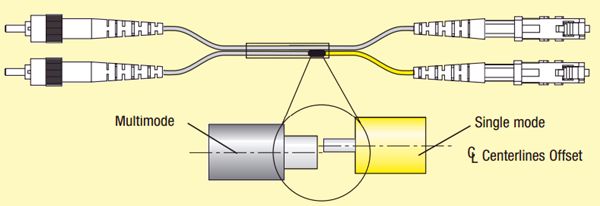

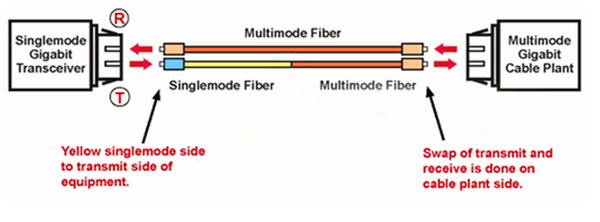

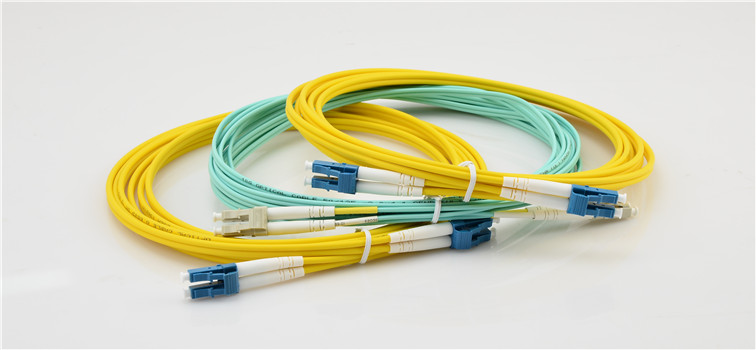

As to fibre optic transceivers, things are more complex. For that fibre optic transceivers require different fibre patch cords which have more types. Fibre patch cables cover single-mode and multimode. Single-mode patch cable can be classified into OS1 and OS2. While multimode cables can be divided into OM1, OM2, OM3, OM4 cable. Different cables are used in different applications. Single-mode cable can support long distance transmission and multimode cable for short distance link. If the transmission distance is shorter than 500 metres, multimode patch cable is suggested. For long distance transmission, single-mode transmission is suggested. You  should also consider that the transmission data rate can also affect the transmission distance. Let’s look at the following point.

should also consider that the transmission data rate can also affect the transmission distance. Let’s look at the following point.

MSA has defined a variety of transceivers that can support different transmission distances and data rates. When you buy a fibre optic transceiver, you will find the data rate, wavelength, distance, etc. on its labeling. The following table show the basic information of most often used transceivers and supported cable type.

| Description | Wavelengh | Data Rate | Cable Type | Distance |

| SX | 850nm | 1G | MM | 500 m |

| LX | 1310nm | 1G | SM | 8 km |

| EX | 1310nm | 1G | SM | 40 km |

| ZX | 1550nm | 1G | SM | 70 km |

| SR | 850nm | 10G | MM | 300 m |

| LR | 1310nm | 10G | SM | 10 km |

| ER | 1550nm | 10G | SM | 40 km |

| ZR | 1550nm | 10G | SM | 80 km |

| SR4 | 850nm | 40G | MM | 100 m |

| SR10 | 850nm | 100G | MM | 100 m |

| LR4 | 1310nm | 40G | SM | 10 km |

As mentioned before, single-mode patch cable is better for long distance transmission and multimode patch cable for short distance transmission. Actually single-mode patch cords can be used for different data rates in both long and short distances. But single-mode fibre optic cable will cost more. To achieve reliable performance in short distances with cost effective solutions, you should know the performance of multimode fibre optic cables. The following chart provides the detailed transmission distances and data rates information for different multimode fibre optic cables over wavelength of 850 nm for your reference.

| Fibre Type | 1G | 10G | 40/100G |

| OM1 | 300 m | 36 m | N/A |

| OM2 | 500 m | 86 m | N/A |

| OM3 | 1 km | 300 m | 100 m |

| OM4 | 1 km | 550 m | 150 m |

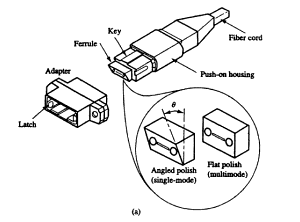

The selection of patch cable for transceiver should also consider the interfaces through which patch cords is connected to the transceiver. In addition, transceiver usually used one port for transmitting and one port for receiving. Generally, fibre optic transceivers usually employs duplex SC or LC interfaces. However, for BiDi transceivers only one port is used for both transmitting and receiving. Thus, simplex patch cord is used with BiDi transceiver.

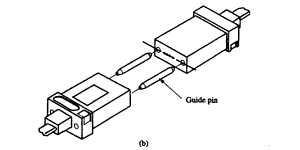

Some 40G/100GBASE QSFP+ transceivers used MTP/MPO interfaces, which should be connected to the network with multi-fibre patch cords attached with MTP/MPO connectors. If these ports are used for 40G to 10G or 100G to 10G connection, then fanout patch cable should be used. For example, a MTP to 8 LC fanout cable can splitter 40G data rate to four 10G data rate.

Next time when you select patch cords for your fibre optic transceivers, you can consider these factors like transmission media, transmission data rate and distance, transceiver interfaces. FS.COM offers a wide range of fibre optic transceivers and patch cords. Custom service is also available. Any problem, please contact us via sales@fs.com.