Patch panel, the critical component in the data centre, comes in various types. The port density of a patch panel may not be your primary consideration, but it indeed matters as the ports directly affects the cable management needs either at present or in the future. The number of these ports vary from 12, 24, 48, 64, 72, 96 to 288 and even more. Actually there is no limit to the number of ports on a patch panel. In this article, I’d like to share a buying guide about 48 port patch panel.

48 Port Patch Panel: Copper VS. Fibre

No matter how many ports they have, patch panels can be deployed in fibre and copper cabling system to organize and distribute cables. The 48 port patch panel is no exception. There is no practical difference in performance as the role of patch panels is to direct signal traffic rather than send the signal. However, there is indeed a difference between the cables they will wire. Fibre patch panel is mainly used in fibre optic cable management, while copper patch panel is designed for both shielded and unshielded copper cables like Cat5e, Cat6, Cat6a, and Cat7.

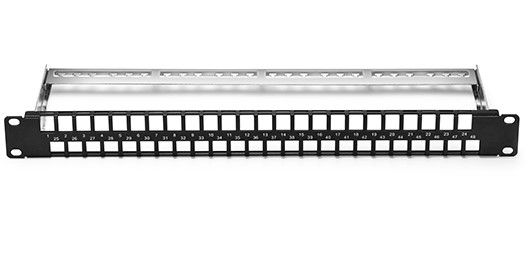

Copper 48 Port Patch Panel Recommendation

As for the copper patch panel, it is designed according to the copper cable types. Sometimes, Cat5e, Cat6 or other Ethernet cables need to be managed in a single panel. In this situation, the blank keystone patch panels can support mixed cabling with installation of different rj45 insert modules. The 48 ports blank keystone/multimedia patch panel, manufactured by FS.COM, is made of SPCC CRS material. It can accommodate all keystone jacks, including RJ45 Ethernet, HDMI audio/video, voice and USB applications. In addition, the high density 19in wide, 1U High, panel design will save valuable space in the rack. With it, you can customize your patch panel according to your specific application.

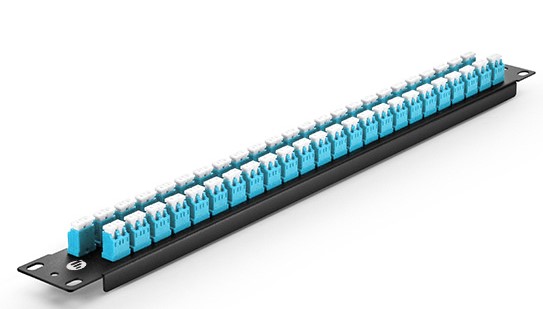

Fibre 48 Port Patch Panel Recommendation

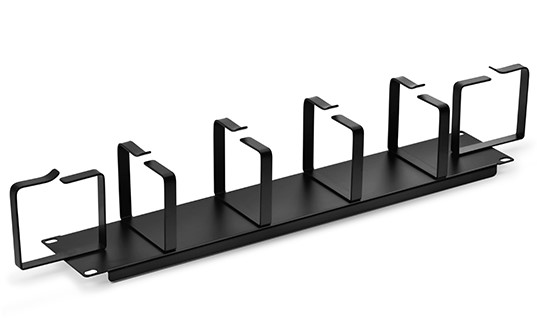

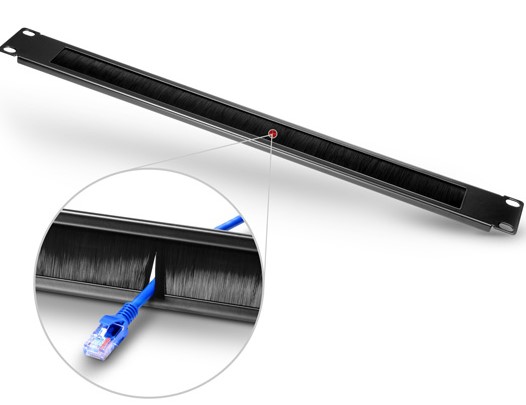

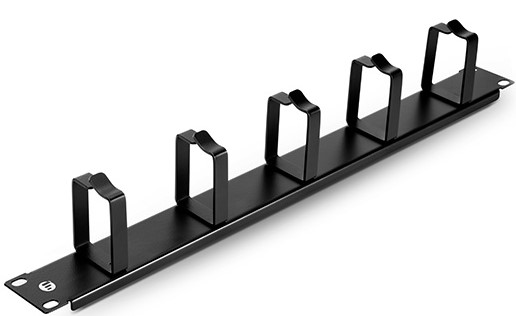

When it comes to 48 port fibre patch panel, you can choose it based on your fibre core, single mode or multimode. 1U 19″ high-density fibre patch panel(ID:69082) can accommodate up to 96 fibres with 48 ports on it. As a fibre patch panel, it supports the OM3/OM4 multimode fibre mode. Designed with LC duplex on both sides, it saves much cost as being fully loaded with fibre couplers. Specifically, FS.COM comes up with an innovative design and cable management. The 1U detachable horizontal cable management panel can protect and organize fibre optic cable in your network.

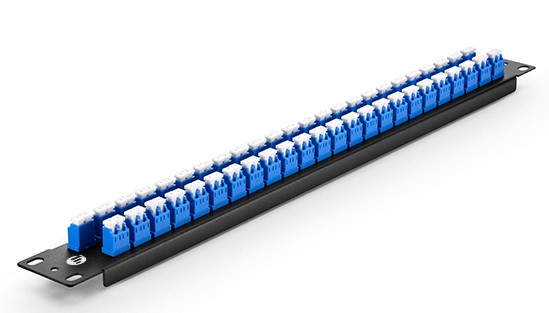

Roughly the same with the former fibre patch panel, this one, 96 fibres, 48 ports LC 9/125 single mode adapters, 1U 19″ high-density fibre patch panel, supports OS2 9/125μm single mode fibre. Designed with high quality steel adapter panel, it is suitable for 1U 19″ frame rack mount or cabinet. It can meets the requirements in backbone-to-backbone and backbone-to-horizontal fibre cabling.

The 48 port patch panels introduced above are all from FS.COM, the company which wins people’s favor by its reasonable price and high quality. This company has been pressing ahead with novel and versatile products and all kinds of cabling solutions.