Undoubtedly, patch panels have become an important component in cabling system, since technological advances open the door to a new generation of more efficient and higher performance data centres. According to different ports, patch panels are commonly divided into 24 port patch panel, 48 port patch panel, 96 port patch panel and even more ports. And all the patch panels can provide a simple, neat and easily managed solution for IT technicians. Today, we’ll focus on 24 port patch panel buying guide.

Why We Use 24 Port Patch Panel

As we know, using a patch panel can enjoy many benefits. It can reduce cable congestion, improve flexibility and scalability and save the valuable space in a sever rack. These contribute to the simplification of manual monitoring, testing, routing and other maintenance on cables. Besides, the 24 port patch panel price is more favorable than other patch panel types. And designed in the same size, the ports distances of 24 port type is not as compact as the 48 port or 96 port ones, which is better for cable connections and cable cooling. This encourages people to choose 24 port type instead of the others.

24 Port Patch Panel: Copper or Fibre

As the backbone of a structured cabling solution, patch panels are available in copper and fibre versions. They are designed to connect different cables. Copper patch panel are used to connect the specific cables like Cat5, Cat5e or Cat6, while fibre patch panel is only applicable for single mode or multimode fibre cables with LC, SC connectors. Thus, before we buy 24 port patch panel, we must know what type of cables that used in our network.

24 Port Patch Panel Recommendation

FS.COM offers a wide variety of 24 port patch panel to help address your specific needs.

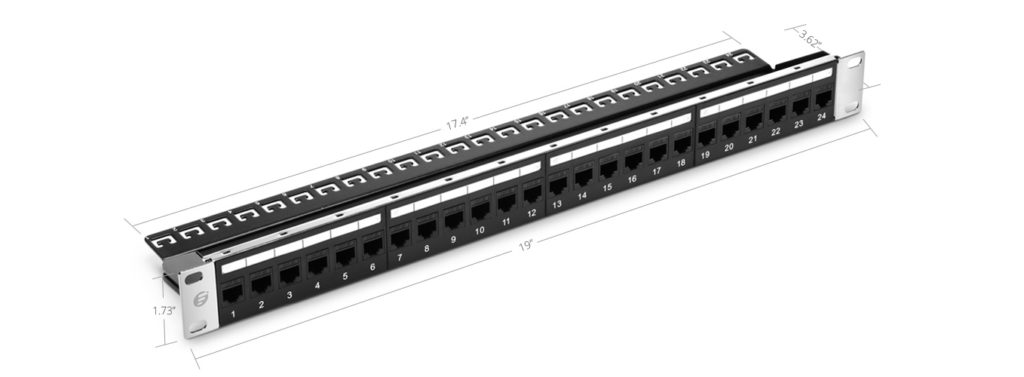

This 1U 24 port patch panel Cat5e features RJ45 couplers on both sides of each panel. It uses the removable design of the rear cable manager, which is conducive to uninstall and install. Also, it adopts the design of self-contained cable management tool, and no extra cable management equipment is needed. This Cat5e patch panel is made of SPCC+ABS materials with an operating temperature from -25℃ to 70℃.

Figure 1: 1U 24 Port Patch Panel Cat5e

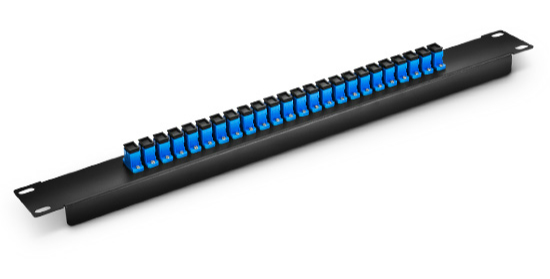

This fibre patch panel is applied to connect OS2, OM3 and OM4 fibre cables. Its sleeve material is ceramic, and its colour-coded couplers will facilitate quick cable type identifications and permit more accessibility during troubleshooting, installation or redeployment.

Figure 2: 24 Port SC Fibre Patch Panel

The 24 port blank keystone patch panel is an ideal tool to manage all copper cables like Cat6 or Cat5e, so you can customize your patch panel and create a perfect mix connection based on your specific applications. The lacing bar with sequential port labels integrated into the panel provides easy identification of multiple types of cables, which can manage cables more efficiently. Designed with the SPCC + ABS plastics, the material is stamped and formed to create a rigid and durable surface capable of withstanding the forces generated while punching down cables to the panel.

Figure 3: 24 Port Blank Keystone Patch Panel

Conclusion

From the above, I suggest if you need to connect copper cables such as Cat5e or Cat6 then choose the 24 port patch panel Cat5e or 24 port patch panel Cat6 type. If your cables are fibre cables, 24 port fibre patch panel is suitable for you. If you want to make the mixed connections, 24 port blank keystone patch panel is the best choice. So if you are ready to buy 24 port patch panel, please don’t be hesitate to visit FS.COM which is a supplier that offers a comprehensive range of patch panels designed to address a variety of needs.