There are many types of polymer coatings used to protect optical fibre from mechanical damage. However, those common polymer-coated fibres are just used for ordinary applications but not for special applications. The special applications including high-stress applications and adverse environments require optical fibres with improved hermeticity, strength and chemical resistance, etc. So what kind of fibres do we need for special applications?

Hermetic optical fibres are thought to be the ideal solution for the special applications. One type of real hermetic coatings for optical fibres is carbon. Carbon coatings on the surface of optical fibre was developed by AT&T Bell Labs. The thickness of the carbon coating on a 125 μm is usually 50 nm. The coating is so thin that fibre surface cannot avoid being damaged even with the most careful handling. So secondary coating is required. However, due to the thin coating, carbon-coated fibres have no additional optical loss, which makes them are a perfect solution in high-speed networks.

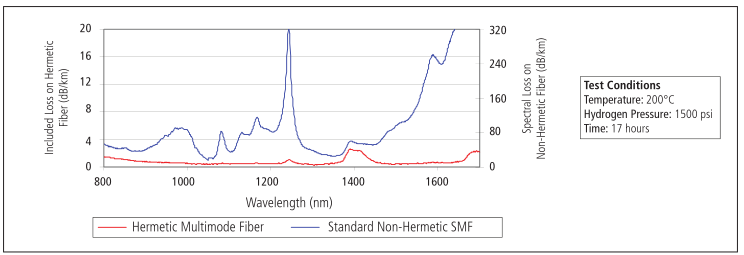

Those kind of carbon-coated optical fibres have three main advantages for its hermetic coatings. The hermetic coatings can protect the fibre surface from water vapor, which reduces static fatigue effects and enhance the fibre mechanical reliability. And they can also defend the fibre surface against mechanical and chemical damage at high temperatures. In addition, those hermetic coatings can stop penetration of hydrogen to the fibre core, making optical networks efficient in hydrogen-containing environment. Here is a picture which shows the attenuation of both hermetic and non-hermetic fibres in a typical operating window for DTS systems. Affected by the hydrogen absorption spectrum, they are of distinct reflections. It is obvious that the optical fibre need to be protected from the hydrogen in diffusion to extend the fibre’s lifetime in a down hole environment.

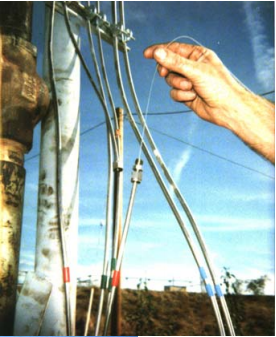

With above advantages, hermetic carbon-coated fibres can be applied for special applications including high-stress applications (tensile stress, bending stress, torsional stress), adverse environment (water, solvents, high operating temperatures, elevated pressures), etc. For instance, hermetic carbon-coated fibres can be deployed down stainless steel tube during oil well completion for distributed temperature sensing. Those fibres, also called optical sensing fibres, are used as distributed sensors to measure temperature, pressure and flowing information of the wells in harsh conditions. The typical down-hole environments usually are at temperatures up to 300℃ and under pressures up to 30,000 psi, which requires hermetic fibres with high reliability. Hermetic carbon-coated fibres are now popular in chemical and oil industry.

With above advantages, hermetic carbon-coated fibres can be applied for special applications including high-stress applications (tensile stress, bending stress, torsional stress), adverse environment (water, solvents, high operating temperatures, elevated pressures), etc. For instance, hermetic carbon-coated fibres can be deployed down stainless steel tube during oil well completion for distributed temperature sensing. Those fibres, also called optical sensing fibres, are used as distributed sensors to measure temperature, pressure and flowing information of the wells in harsh conditions. The typical down-hole environments usually are at temperatures up to 300℃ and under pressures up to 30,000 psi, which requires hermetic fibres with high reliability. Hermetic carbon-coated fibres are now popular in chemical and oil industry.