As massive amounts of data are transferred and stored across the globe, many organizations are placing greater emphasis on network performance to provide great customer service and build a fast and reliable network for their employees. Improving network connectivity in data centers is one of the most basic and critical ways to optimize network and hybrid architecture. When it comes to the connection between the horizontal cabling and active equipment such as switches, there are two basic configurations that are interconnect and cross connect.

Interconnect and Cross Connect Basics

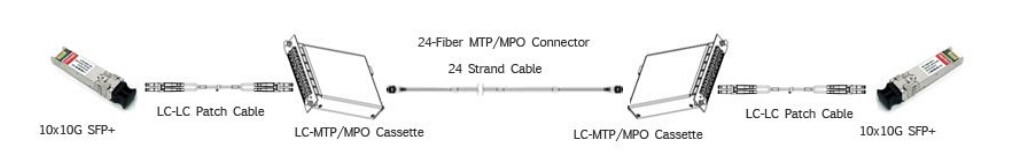

Interconnect in data center is to use a patch panel on the active equipment to distribute links from device to other devices in the data center, commonly known as the distribution panel. In an interconnect system, patching is done directly between the active equipment and the distribution patch panel. More specifically, outlets are terminated to a patch panel, and the patch panel is then patched directly to a switch, as shown in the figure below.

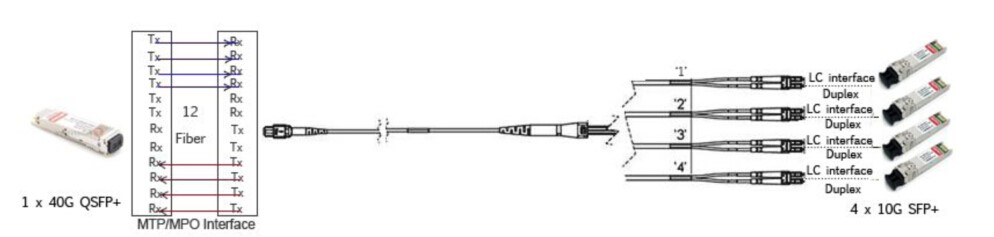

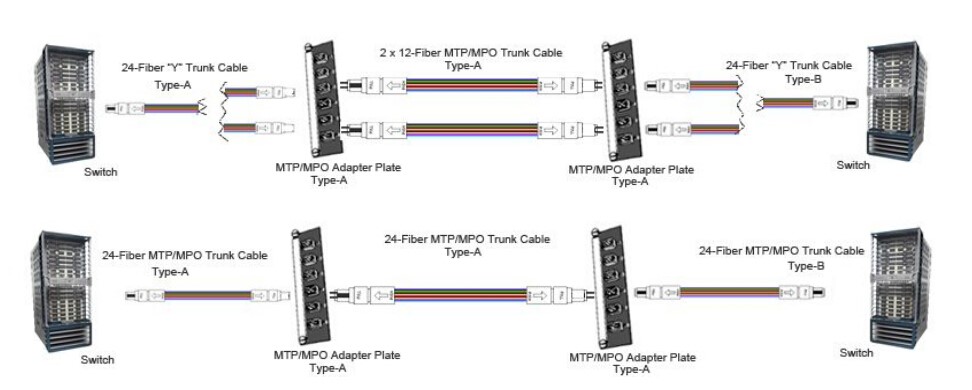

A cross connect in data center is the use of additional patch panels to mirror the ports of the equipment being connected, essentially creating a separate patching zone that provides connection between different equipment by patch cords. In a cross-connect system, the switch ports are replicated on the additional patch panel, also called equipment patch panel, and patching is carried out between the equipment patch panel and the distribution patch panel. Basically, there are two types of cross-connects, which are three-connector cross-connect and four-connector cross connect.

The structure of a three-connector cross connect is similar to interconnect mentioned above, just adding a cross-connecting process at the switch end, as shown below.

Four-connector cross connect usually requires a patch field which is usually an individual cabinet. In this case, two copper trunk cables are working as permanent cables, making the cabling system easier to manage.

Interconnect Vs Cross Connect: How to Choose?

Currently, most cabling systems use interconnect design. But some people indicate the cross connect is preferred as it increases the reliability of the system. Choosing the right cabling system should be based on the needs of data center connectivity combining these two systems’ cost, security and management, as discussed below.

Costs

The cross connect design doubles the number of patch panels needed, which obviously requires more cabling and connectivity, and places more connectivity points (and therefore insertion loss) into a channel. Therefore, an interconnect design is quicker, easier and cheaper to deploy than a cross connect design and provides better transmission performance.

Security

A cross connect cabling involves a dedicated patching area that isolates mission-critical active equipment away from the passive patch zone, thus preventing any tampering with sensitive equipment ports during routine maintenance. Therefore, the cross connect design can improve reliability as it reduces misoperations and ensures fast fault recovery.

Management

Compared to interconnect systems, the cross connect design offers prominent advantages in management. In a cross connect system, the cables connected to switches and servers can be fixed and regarded as permanent connections. When moves, additions, and replacements are required, maintenance personnel only need to change the jumpers between patch panels, whereas it is inevitable to plug and remove the cables of the switch and server ports in interconnect systems. However, even though the interconnect system does not have a dedicated patching area to simplify management, it requires less rack space, which may be favored by communication rooms with limited space.

Conclusion

Cross connect design doubles patch panels and requires more cabling and connectivity than interconnect design, resulting in more rack space and significantly higher costs, but it simplifies management and improves reliability for data centers. Organizations can choose the right cabling system based on their actual situation and needs.

Article Source: Interconnect and Cross Connect in Data Center

Related Articles: