When the fibre patch panel is loaded with cables, your cabling is almost finished with the core elements all ready. You can achieve fast and smooth Ethernet connectivity. But turning around, you may find a mess caused and left by the installation. The slack cables without careful comb are hung casually, resulting in a sloppy look just like the noddles being stirred. If we have a look at an expert, it is common to find that they all manage their cables in a good order. And today, we will reveal the secret of the marvelous layout — horizontal and vertical cable management.

Horizontal and Vertical Cable Management

When you try to simulate others’ cabling system, you will inevitably find that the cable management comes in two varieties, horizontal and vertical. When installing cables in a fibre enclosure, you will undoubtedly have to run them both vertically and horizontally. The best solution for this cabling is to run all the cables horizontally from the server directly to the vertical cable management rack.

With these two solutions, you can gain many benefits like enhanced availability through reduced downtime, and improved system performance through reduced crosstalk and interference. We all know that crosstalk is harmful and will damage more or less the data transmission. What’s more, it enables us easier and safer access to individual components so as to achieve improved maintenance and serviceability. And the moves, adds and changes will be simplified.

Horizontal and Vertical Cable Manager

With horizontal cable managers, the cables from equipment in racks can be routed neatly and properly and away from damage. If you are using flat-faced patch panels or network switches form which cables come above or below, horizontal cable manager will complete the support pathway for patch leads between the cabling section and the exact connection point (port) on the patch panel or switch. Alternately, horizontal management can be used to create rack-to-rack pathways for patch leads. The FS.COM finger duct horizontal cable manager is designed with flexible fingers, rear pass-through holes and a removable cover. It can be mounted to standard 19 and server racks and cabinets providing well-organised cabling quickly and easily. 1U and 2U versions are both available at FS.COM.

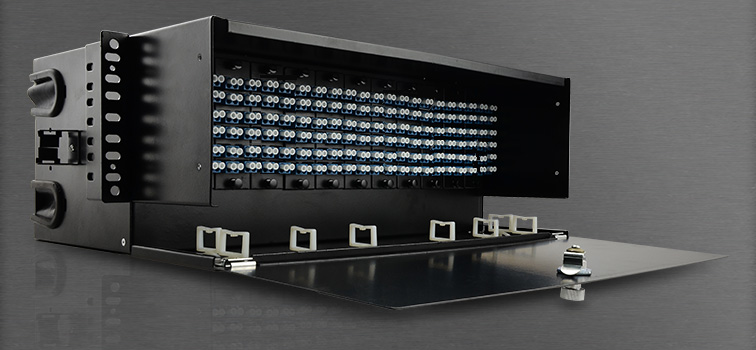

Vertical cable manager just as seen in the below image, utilises the additional space at the both sides of the cabinet to manage the slack from patch leads, and make sure that they can easily route the largest cable diameter in your plan. For static environments, you can consider installing another vertical cable manager behind the racks, which does not block access to components in the space between the racks. Vertical racks can be also installed under a desk or against a wall and accommodate networking equipment up to 4 RU. Its dual sided fingers enable both front and back well-organised cabling.

Conclusion

With horizontal and/or vertical cable managers, the human errors which may be committed previously due to the confusion of a mess of cables can be easily prevented in horizontal and vertical cable management. Once you have to deal with fibre and copper cables at the same time, apart from our multimedia modular panel, FS.COM cable managers can be used to house and organise fibre and copper cabling while keeping separation between the two.