Fibre rack mount enclosures can provide a high-density solution for inter-connects or cross-connects between backbone horizontal cable and active equipment. Enclosures allow for easy field termination of connectors or installation of pre-terminated solutions, and are ideal for high-density fibre applications in data centres, equipment rooms, and central offices. Fibre rack mount enclosures come in different configurations. You may find fibre enclosures in the market with different sizes, slide-out or lid type, fixed front panel or removable front panel, splice tray or preterminated. Among so many types, you have to choose one that suits your application the most. So how to make the right decision? The following will tell you the method.

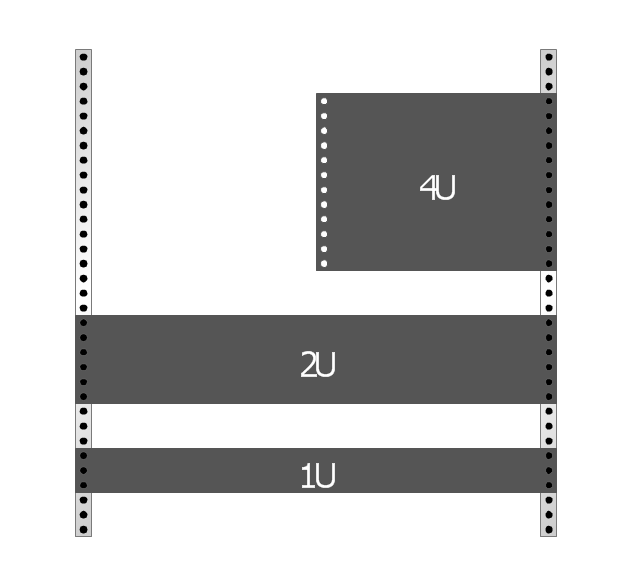

The rack mount units are designed for rack mounting in 19-in (48 cm) racks. They are available in rack space options of 1U (two panels, cassettes or modules), 2U (four panels, cassettes or modules), 3U (six panels, cassettes or modules) and 4U (twelve panels, cassettes or modules), etc.(See the following picture.) You should choose the most proper one depending on the space and port requirement of your project.

The rack mount enclosures include two kinds. One is the slide-out type, and the other incorporates a removable lid. The slide out type is more expensive while the lid type is less expensive but requires the user to remove the whole enclosure from the rack to gain internal access. If your budget is sufficient, I will recommend you to use the slide-out type. Then you may get more benefits during installation and maintenance, as they respectively feature a convenient slide-out support tray and a integrated swing-out tray so that you don’t need to remove the whole enclosure from the rack to gain internal access.

As we know, fibre optic adapters are the key part of an enclosure to accept the various fibre optic connectors. Thus, to choose a proper front panel option is also important. For general rack mount enclosures, there are mainly two types—one type uses fixed 1U High 19” front panel, and the other type incorporates three, or even up to five removable front panels. The latter is now becoming more popular with users, because a plug & play fibre adapter panel solution assures flexibility and ease of network deployment and MAC (moves, adds, and changes).

Pigtail splicing and pre-terminated assemblies are the two basic way to do fibre termination. Depending on which method you choose, there are some differences in the rack mount enclosure selection. For pigtail splicing, you may need a rack mount panel with fibre splice tray, which are used for efficient management and storage of the spliced optical fibres. Splice tray is used for efficient management and storage of the spliced fibre optic cables. Fibre optic adapters are installed into the cut outs in the enclosure to accept the various fibre optic connectors. Fibre optic pigtails mate with the adapters and the fusion-spliced tails are stored on the splice tray.

But if you apply pre-terminated assemblies, the inner configuration of the rack mount panel is only the spools that are used to organize the cables. Obviously, the pre-terminated solution will help you save more installed time and labor cost.

In this article, you are advised to select the best fibre rack mount enclosure suitable for your own application from so many types. FS.COM offers a wide range of rack mount enclosures, which is good for interconnect and cross-connect in building your data centres. It’s ideal for the organization and protection of optic backbone terminations. Any service need, please contact us via sales@fs.com or call 24/7 Customer Service: 1 (718) 577 1006.