Enterprise switches play a vital role in modern network architectures, facilitating efficient and secure data transfer within an organization. The Basic license provides standard features, while the Advanced license takes enterprise switches to a whole new level of power and functionality. This article aims to explore the concept of premium licenses in enterprise switches, highlight their importance and delve into the additional features and benefits they offer. We will also focus on the advanced license options available in FS Enterprise Switches, showcasing their capabilities and benefits.

Advanced License Basics

An advanced license is a type of high-level software license, which is not a tangible product but a software package. The advanced software license supports multiple advanced features such as MPLS, LDP, MPLS L2VPN, MPLS L3VPN, VXLAN-BGP-EVPN, IPFIX, etc. In enterprise switches, licenses act as authorization keys that unlock specific features and modules within the switch’s firmware.

Basic licenses typically provide standard functionalities such as data forwarding and basic security features. However, advanced licenses offer a wide range of additional functionalities and advantages, such as increased port counts, support for advanced routing protocols, and more granular traffic control. By understanding the different types of licenses, organizations can make informed decisions, select the appropriate license for their specific needs, and effectively take advantage of the features provided.

Unleashing the Full Potential of Advanced License

To fully unleash the potential of advanced licenses in enterprise switches and optimize network performance and security, organizations can leverage the following functionalities:

- VLAN Partitioning: With advanced licenses, organizations can divide their switches into multiple Virtual Local Area Networks (VLANs). This enhances network security and provides greater management flexibility.

- Quality of Service (QoS): Advanced licenses empower organizations to prioritize network traffic based on specific criteria, such as application type, source, or destination. This ensures that critical applications receive the necessary bandwidth and guarantees a higher quality user experience.

- Advanced Routing Protocols: Advanced licenses often include support for advanced routing protocols such as Open Shortest Path First (OSPF) or Border Gateway Protocol (BGP). These protocols enable efficient and scalable routing within enterprise networks, enhancing network stability and performance.

- Traffic Monitoring and Analysis: Advanced licenses may offer features for traffic monitoring and analysis, allowing organizations to gain insights into network traffic patterns, identify potential bottlenecks, and proactively optimize network performance.

- Enhanced Security Features: Advanced licenses can provide additional security features such as Access Control Lists (ACLs) and Secure Shell (SSH) protocols. These features enhance network security by allowing organizations to control access to network resources and encrypt network communications.

FS Enterprise Switches with Advanced Licenses

FS Enterprise Switches with Advanced Licenses are suitable for organizations that require robust performance, scalability, and advanced networking capabilities. The S5800-48T4S is an FS enterprise switch with an advanced license. Built with advanced hardware and software, the S5800-48T4S delivers a robust Layer 3 routing solution for next-generation enterprise, data center, Metro, and HCI networks. Here are some key details about FS Enterprise Switches:

- Advanced License Functions: The Advanced License includes a range of advanced networking functions to enhance the capabilities of the switches. These functions include MPLS, LDP, MPLS-L2VPN, MPLS-L3VPN, VxLAN-BGP-EVPN, and IPFIX.

- Network Protocols and Features: The switch supports multiple network protocols and features to optimize network performance and security. These include MLAG for link aggregation and redundancy, a DHCP server for automatic IP address assignment, and support for IPv4 and IPv6 routing.

- Management and Monitoring: FS Enterprise Switches with Advanced Licenses offer comprehensive management and monitoring capabilities. They support protocols like SNMP for network monitoring and can be managed using software-defined network (SDN) solutions through RPC-API.

- Security Features: The switches provide advanced security features to protect the network and ensure secure access. These features include support for ACL for traffic filtering, MAC whitelisting for controlling access based on MAC addresses, ARP inspection for preventing ARP spoofing attacks, IP source guard to validate IP packet sources, and IEEE802.1X RADIUS authentication for secure user access.

ConclusionAdvanced licenses in enterprise switches unlock powerful functionalities that enhance network performance and security. FS enterprise switches offer comprehensive advanced license options to meet diverse network requirements. By leveraging advanced licenses, organizations can optimize their network infrastructure and achieve a robust and efficient network. If you want to learn more, please visit FS.com.

Related Articles:

Introducing the Advanced License of Enterprise Switches | FS Community

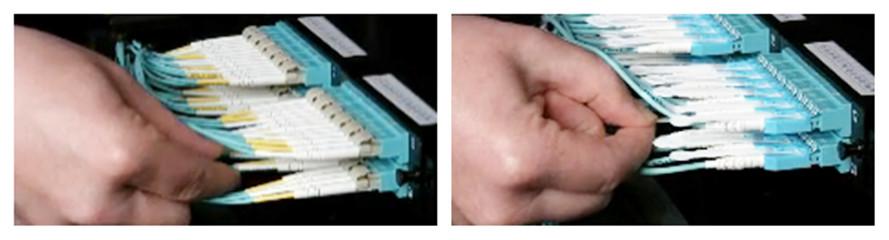

As fibre deployment has become mainstream, splicing has naturally crossed from the outside plant (OSP) world into the enterprise and even the data centre environment. Fusion splicing involves the use of localized heat to melt together or fuse the ends of two optical fibres. The preparation process involves removing the protective coating from each fibre, precise cleaving, and inspection of the fibre end-faces. Fusion splicing has been around for several decades, and it’s a trusted method for permanently fusing together the ends of two optical fibres to realize a specific length or to repair a broken fibre link. However, due to the high costs of fusion splicers, it has not been actively used by many people. But these years some improvements in optical technology have been changing this status. Besides, the continued demand for increased bandwidth also spread the application of fusion splicing.

As fibre deployment has become mainstream, splicing has naturally crossed from the outside plant (OSP) world into the enterprise and even the data centre environment. Fusion splicing involves the use of localized heat to melt together or fuse the ends of two optical fibres. The preparation process involves removing the protective coating from each fibre, precise cleaving, and inspection of the fibre end-faces. Fusion splicing has been around for several decades, and it’s a trusted method for permanently fusing together the ends of two optical fibres to realize a specific length or to repair a broken fibre link. However, due to the high costs of fusion splicers, it has not been actively used by many people. But these years some improvements in optical technology have been changing this status. Besides, the continued demand for increased bandwidth also spread the application of fusion splicing.