FTTH, short for fibre to the home, is the installation and use of optical fibre from a central point directly to individual buildings such as residences, apartment buildings and businesses to provide unprecedented high-speed Internet access. In determining the best solution for a particular FTTH deployment, providers must first decide between splices and connectors. Then, they must choose the best splice or connector for the particular circumstances of deployment. This article explores the available interconnect solutions for FTTH drop cables and discusses their advantages and disadvantages in various deployment circumstances.

Splice vs Connector

Before deploying a FTTH network, providers must first decide whether to use a splice, which is a permanent joint, or a connector, which can be easily mated and un-mated by hand. Both splices and connectors are widely used at the distribution point. At the home’s optical network terminal (ONT) or network interface device (NID), either a field-terminated connector or a spliced-on factory-terminated connector can be used.

Splices enable a transition from 250micron drop cable fibre to jacketed cable with high reliability and eliminates the possibility of the interconnection point becoming damaged or dirty. Splices are most appropriate for drop cables dedicated to a particular living unit where no future fibre rearrangement is necessary, such as in a greenfield or new construction application where the service provider can easily install all of the drop cables during the living unit construction.

Connectors are easier to operate and provide greater network flexibility than splices, because they can be mated and unmated repeatedly, allowing them to be reused over and over again. Connectors also provide an access point for network testing. However, connectors cost more than splices although network rearrangement is much cheaper. Therefore, providers must weigh the material cost of connectors along with the potential for contamination and damage against their greater flexibility and lower network management expense.

Choosing the Right Splice

Splicing technology for FTTH deployment falls into two major categories: fusion and mechanical.

Fusion splicing is considered to be a solution for FTTH drop splicing, especially considering it provides a high quality splice with low insertion loss and reflection. However, fusion splicing is expensive and requires trained technicians to operate. It is time-consuming and the slow installation speed hinders its status as the preferred solution. Fusion splicing is best suited for companies that have already invested in fusion splicing equipment and do not need to purchase additional splicing machines.

Mechanical splices can perform well in many environments and have been successfully deployed around the world in FTTH installations. A typical mechanical fibre optic splice includes a small plastic housing with an aluminum alloy element to precisely align and clamp fibres. An index matching gel inside the splices maintains a low-loss optical interface, which results in an average insertion loss of less than 0.1 dB.

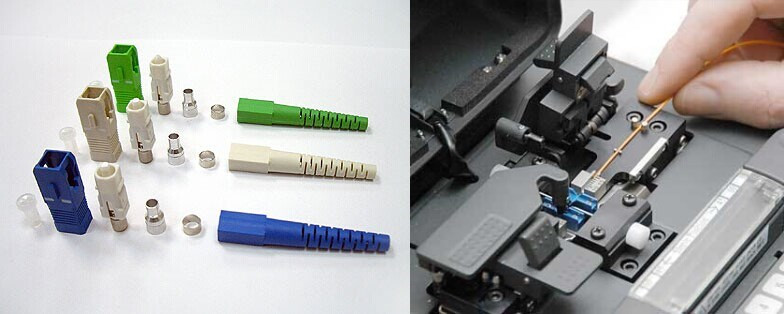

Choosing the Right Connector

According to the drop cables used, connectors can be divided into two types: factory-terminated and field-terminated.

Factory-terminated

Factory-terminated drop cables can provide high-performing, reliable connections with low optical loss. Factory termination also keeps labor costs low by reducing installation time. An excellent application is a patch cord that connects a desktop ONT to a wall outlet box inside the living unit. A key failure point in the network is when the end user accidentally breaks the fibre in the cable that connects the desktop ONT. If this occurs, the patch cord can be easily replaced. However, factory-terminated cables can be expensive compared to field-terminated alternatives.

Field-terminated

Many providers prefer field-terminated connectors where the installation can be customised by using a reel of cable and connectors, such as fuse-on connectors and mechanical connectors. For example, fuse-on connectors use the same technology as fusion splicing to provide the highest level of optical performance in a field-terminated connector. By incorporating the fusion splice inside the connector, the need for a separate splice tray has been eliminated. However, fuse-on connectors share many of the same drawbacks as fusion splicing. They require expensive equipment, highly trained technicians, and packing and unpacking time, and a power source, ratcheting up installation costs. However, mechanical connectors can provide alternatives to fuse-on connectors for field installation of drop cables.

Summary

The drop cable interconnect solution comprises a key component of an FTTH network. Reliable broadband service depends upon robust connections at the distribution point and the NID/ONT. Choosing the right connectivity product can result in cost savings and efficient deployment while providing reliable service to customers. Globally, most FTTH drop cable installations have been and continue to be field-terminated on both ends of the cable with mechanical connectivity solutions.