Passive optical network (PON) has been widely applied in the construction of FTTH (fibre to the home). With PON architecture, network service providers can send the signal to multiple users through a single optical fibre, which can help them save great costs. To build the PON architecture, optical fibre splitter is necessary.

The fibre splitter is a passive component specially designed for PON networks. Fibre splitter is generally a two-way passive equipment with one or two input ports and several output ports (from 2 to 64). Fibre splitter is used to split the optical signal into several outputs by a certain ratio. If the ratio of a splitter is 1×8 , then the signal will be divided into 8 fibre optic lights by equal ratio and each beam is 1/8 of the original source. The splitter can be designed for a specific wavelength, or works with wavelengths (from 1260 nm to 1620 nm) commonly used in optical transmission. Since fibre splitter is a passive device, it can provide high reliability for FTTH network. Based on the production principle, fibre splitters include Planar Lightwave Circuit (PLC) and Fused Bionic Taper (FBT).

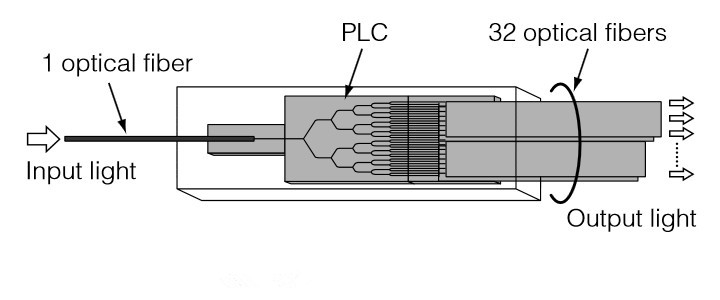

PLC splitters are produced by planar technology. PLC splitters use silica optical waveguide technology to distribute optical signals from central office to multiple premise locations. The output ports of PLC splitters can be at most 64. This type of splitters is mainly used for network with more users.

Internal Structure

The following figure shows a PLC splitter. The optical fibre is splitted into 32 outputs. PLC chip is made of silica glass embedded with optical waveguide. The waveguide has three branches of optical channels. When the light guided through the channels, it is equally divided into multiple lights (up to 64) and transmitted via output ports.

Outside Configuration

Bare splitter is the basic component of PLC fibre splitter. For better protection of the fragile fibre and optimised use, PLC splitters are often equipped with loose tube, connector and covering box. PLC splitters are made in several different configurations, including ABS, LGX box, Mini Plug-in type, Tray type, 1U Rack mount, etc. For example, 1RU rack mount PLC splitter (as shown in the figure below) is designed for high density fibre optical distribution networks. It can provide super optical performance and fast installation. This splitter is preassembled and fibres are terminated with SC connectors. It’s ready for immediate installation.

FBT splitters are made by connecting the optical fibres at high temperature and pressure. When the fibre coats are melted and connected, fibre cores get close to each other. Then two or more optical fibres are bound together and put on a fused taper fibre device. Fibres are drawn out according to the output ratio from one single fibre as the input. FBT splitters are mostly used for passive networks where the split configuration is smaller.

Fiberstore offers a wide range of PLC splitters that can be configured with 1xN and 2xN. Our splitters are designed for different applications, configurations including LGX, ABS box with pigtail, bare, blockless, rack mount package and so on.

| Port Configuration | Package Style | Fibre Diameter (Input/output) |

Connector (Input/output) | Pigtail Length |

| 1×2 | Steel tube, bare fibre | 250μm | None | 1.5m |

| 1×4 | Mini module | 900μm | SC APC/UPC | 2.0m |

| 1×8 | Pigtailed ABS box | 2.00mm | LC APC/UPC | 3.0m |

| 1×16 | Mini plugged-in | 3.0mm | FC APC/UPC | Customised |

| 1×32 | LGX | ST APC/UPC | ||

| 1×64 | Splice Tray Type | Customised | ||

| 2×16 | Rack mount |

Fibre splitter is an economical solution for PON architecture deployment in FTTH network. It can offer high performance and reliability against the harsh environment conditions. Besides, the small sized splitter is easy for installation and flexible for future network reconfiguration. Therefore, it’s a wise choice to use fibre splitter for building FTTH network.