The fibre optic patch panel, one type of the patch panels, is getting more popular with many expertise and customers getting to use it. It rides the waves of the optic product and meets appropriately our demands. As the fibre is fed through a coupler, the fibre patch panels are a lot easier to install and no hardwiring is needed.

What Is a Fibre Optic Patch Panel?

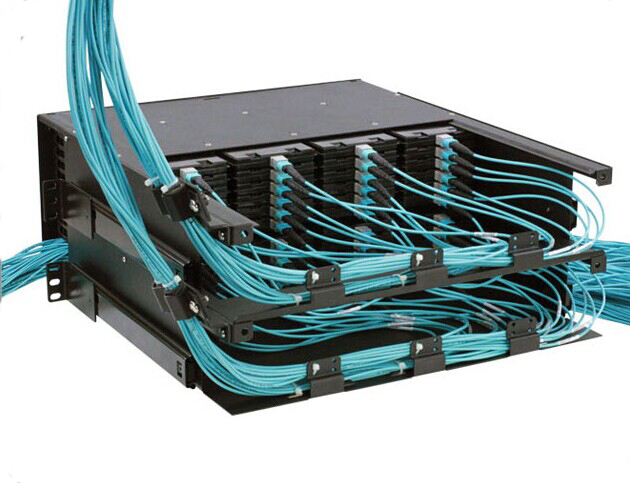

Fibre optic patch panel, also known as fibre distribution panel, serves as a convenient place to terminate all the fibre optic cable running from different rooms into the wiring closet and provides connection access to the cable’s individual fibres. Fibre patch panels are termination units, which are designed with a secure, organised chamber for housing connectors and splice units. Fibre patch panels are available in rack mounted or wall mounted and are usually placed close to terminating equipment (within patch cable reach). Both types can house, organise, manage and protect fibre optic cable, splices and connectors. Rack mount panels also come in flat and angled versions.

Why We Use Fibre Optic Patch Panel to Manage Cables?

Of course, if we skip it and just connect all cables directly into the hub, then we will miss the following advantages:

You can label the patch panel so you know which room the cable run goes to. Putting the labels on the cables is tougher to read than labels on a patch panel and there is also a risk of falling off. Having patch panel will become very handy and achieve neat cabling.

Best Practices in the Installation of a Fibre Patch Panel

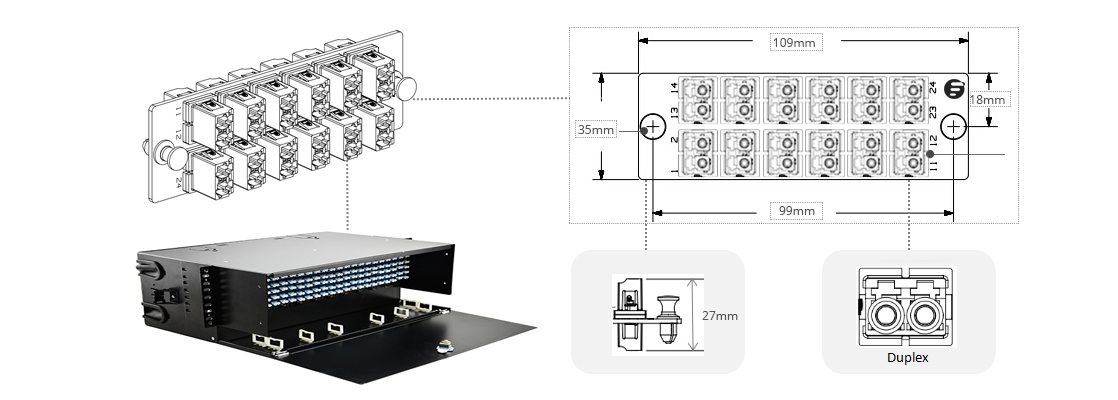

In this part, we will use a 12 port rack mount fibre optic patch panel as an example. And the main body can be divided into 3 parts, namely cable preparation, splicing, and patch cable installation.

First, prepare fibre optic cable or blown tube as required and secure the network cable to the rear of the panel by using cable ties. For the easy operation, we need to unscrew and remove the splice tray. In addition, we need to cut the cable jacket off to punch down but avoid excess to limit crosstalk or damage. Then, splice input fibres onto the pigtails or field terminate connectors as applicable. Finally, put the cables in the panel form its back. Remove the protective covers of both the adapter and the connector and clean the connectors and place them in the adapters.

Conclusion

In a few words, a fibre optic patch panel gives you a very good cabling organisation. The better cable management can spare you a lot of energy and time in case that you do trivial things. Though many people view it as a waste, I believe that everything has its meaning to exist in the world. What matters most is whether you can take advantage of it and apply it to the situation where it is actually needed.